4000 components, instead of 40: Unbeatable tool lives with the high-performance reamer

KIPP was facing a challenge: Their cast-steel products need to be equipped with through-holes with µ-level precision. With the HR 500 high-performance reamer, KIPP no longer has to worry about poor dimensional accuracy or short tool lives.

Everything under control? The GTMS basic module

Optimise your manufacturing process with Gühring Tool Management Software (GTMS). Effortlessly monitor tool usage and inventory levels, avoid the build-up of unused stock and increase efficiency. The GTMS basic module offers full control.

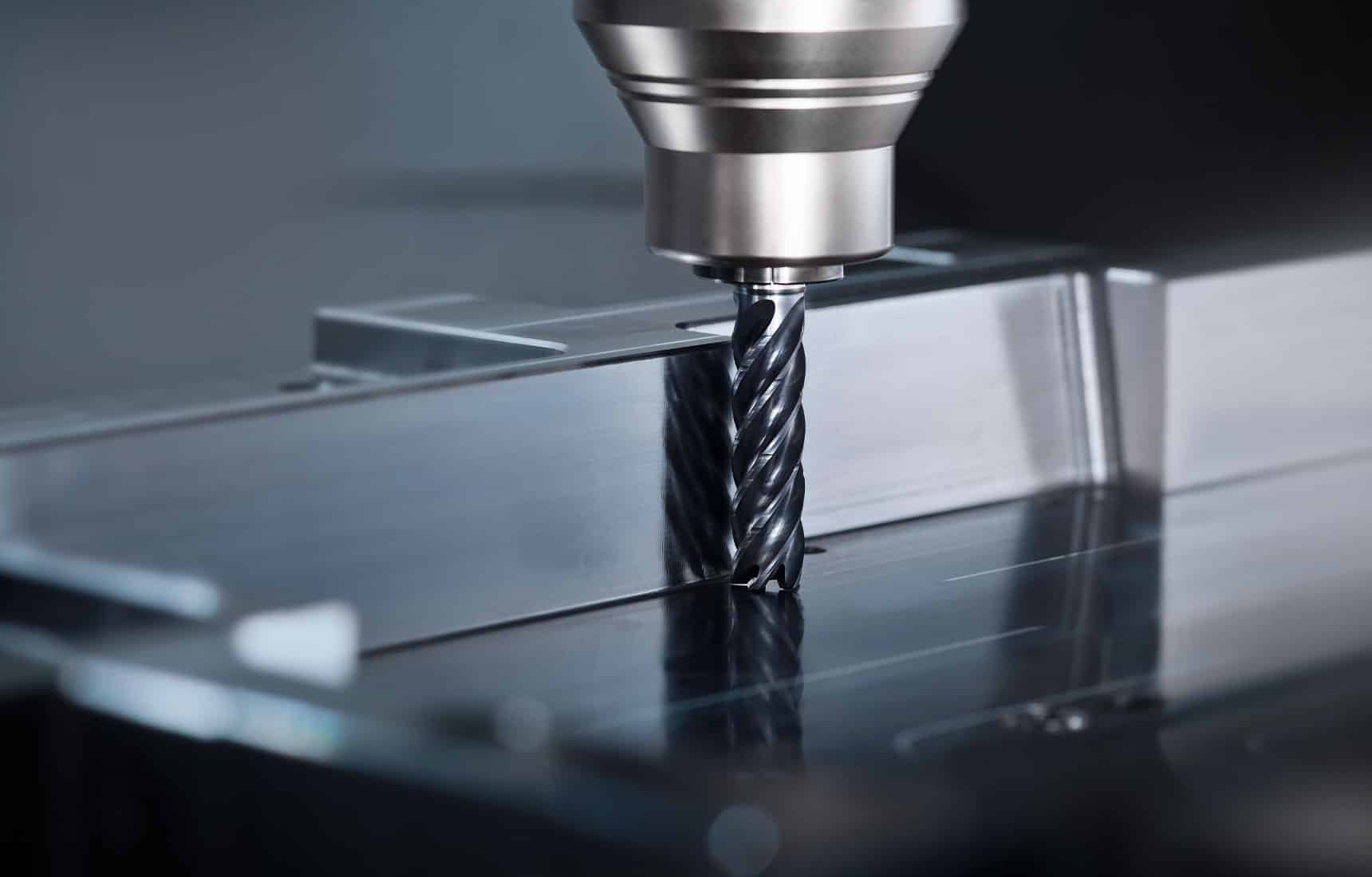

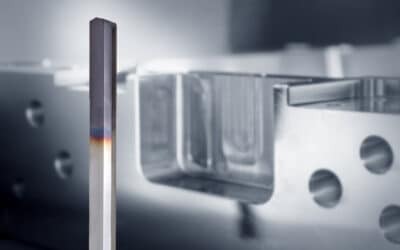

Fast and dynamic: Trochoidal milling in mould making

One milling strategy has proven to be particularly successful for mould making, where sometimes very hard materials have to be machined in the shortest possible time: GTC milling. This form of trochoidal milling results in particularly long tool lives during machining.

Combating wear with diamond: Magnesium machining in e-mobility

A customer encounters wear problems in the production of magnesium parts for electric motors: With special diamond tools, Gühring increases the tool life from weeks to a year. This saves the company time and money.

Gühring General Catalogue: Swiss pocket knife for your success

One for all, all in one – Meet the new General Catalogue from Gühring. It contains everything you need for success: All tools for your machining tasks, including accessories and cutting data.

Mould and die: hard machining shortens processes

Competitive pressure in mould making is forcing Vogt AG to shorten its lead times by means of hard machining. Tools from Gühring offer innovative solutions for machining hardened steel up to 54 HRC.

Milling length selection: Our sharpest solid carbide milling cutter in all variants

Discover how choosing the right length when milling with the RF 100 Sharp improves the quality of your work and relieves your budget. This is because in the world of construction and manufacturing, the right length selection means not only precision, but cost-effectiveness as well.

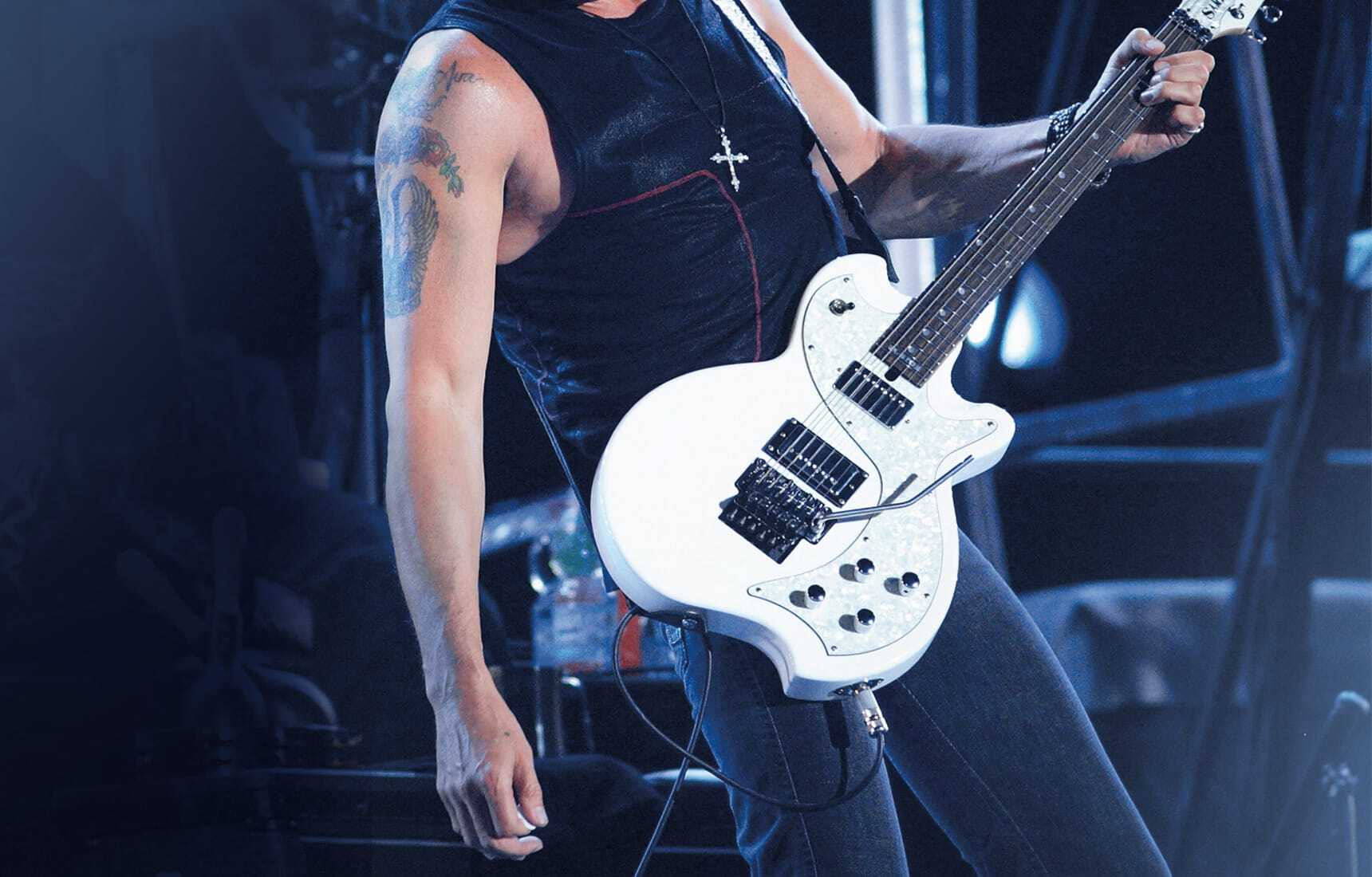

High-volume milling: Solid carbide milling cutter eliminates vibrations

Discover the solution for vibration-free high-volume milling: The Gühring solid carbide milling cutter RF 100 Speed excels in the production of guitar parts with high running smoothness and 25% longer tool lives – ideal for roughing in various materials.

Test equipment management: Software stays on top of measuring equipment

Wherever components are manufactured with high precision, regularly calibrated measuring instruments are essential. This company has switched to digital measuring equipment management with GTMS – and is saving itself a lot of time as a result.

IBAG saves 70 % of its machining time when micro-drilling in stainless steel

IBAG’s success with Gühring: The ExclusiveLine micro-precision drill for stainless steel saves 70 % machining time for high-performance spindles. Gühring’s high-precision tools improve position accuracy and enable the finest holes to be created in high-alloy steels.

Small box, full control: Tool management with the Minibox

Die neue TM-Minibox erweitert das Portfolio der Gühring Tool Management Automaten und bietet Flexibilität und digitale Effizienz. Flexibel, kompakt, digital – das ist maximale Werkzeugverwaltung im Miniformat.

From difficult-to-machine to aluminium: 3 new material specialists

Discover three new specialists from Gühring for reliable drilling in stainless steel materials, titanium and aluminium. They guarantee optimum results thanks to their extra smooth surfaces, polished flutes and effective internal cooling.

Universal talent for aluminium: The new PCD Diver

Maximum machining rates and neverending tool lives in aluminium: The new PCD Diver from Gühring promises both. Thanks to its innovative geometry, the tool guarantees top quality with low power consumption and high stability.

Cross holes? Not a problem! With the right deep drilling strategy

The machining of intersecting deep holes can be tricky: This is because the cooling process is interrupted, creating an adverse spot drilling or guidance situation. Gaps can only be bridged with the right strategy.

Be it ceramic or carbide: Diamond nozzle has been printing without wear for three years

AIM3D encountered a problem when 3D printing with carbide: The nozzles only lasted for a short time. A new diamond nozzle from Gühring changed everything.